Table Of Content

This article will help explain your options, the design’s appearance, and how you can determine which type to select. The arch bridge carries loads primarily by compression, which exerts on the foundation both vertical and horizontal forces. Arch foundations must therefore prevent both vertical settling and horizontal sliding. In spite of the more complicated foundation design, the structure itself normally requires less material than a beam bridge of the same span. While trusses have been used for both roofs and bridges for many centuries, there was an explosion of truss advancement in the 19th century in America. The need for bridges to span longer distances in this era, as well as to hold increasingly heavy loads, brought about many creative solutions in the form of new truss designs.

Arch

Strauss apparently wasn't aware of the importance of safety in bridge construction however, and in the end he fired Ellis from the job. Not only did he then give Ellis no credit for the engineering work he did, he did something even worse and actually removed Ellis' name from all materials relating to the bridge. Also, Charles Ellis' name does not appear on the plaque for the bridge. When it comes to bridge construction, selecting the best truss design is a critical decision that influences the bridge’s strength, stability, and overall performance. Truss bridges, known for their efficient use of materials and ability to span long distances, come in various designs, each suited to specific engineering requirements. In this blog post, we’ll delve into different types of truss bridges and discuss considerations for selecting the best truss design.

Design of the Bottom Chord

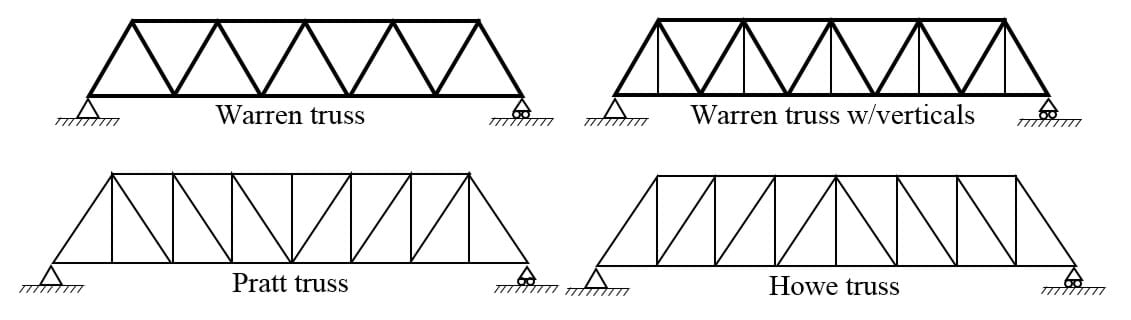

Trusses are popular because they use a relatively small amount of material to carry relatively large loads. Furthermore, engineering strategies are employed to enhance the stability and integrity of truss bridges. Bracing systems, such as diagonal members and vertical supports, are incorporated to resist lateral forces and maintain structural integrity. Truss configurations, such as Pratt, Warren, or Howe trusses, are carefully chosen based on the specific bridge span and loading conditions. Lattice truss structural systems have been employed in constructing railway and highway bridges with great success for so many years.

Building Model Bridges

If you do not know how to start designing your own bridge, I would recommend the Warren, or the Pratt or Howe trusses. The four primary materials used for bridges have been wood, stone, iron, and concrete. From iron, steel is made, and steel is used to make reinforced and prestressed concrete. Modern bridges are almost exclusively built with steel, reinforced concrete, and prestressed concrete. I have chosen to highlight these four examples of different trusses to get you started with some very solid examples that you can easily use on your bridge. I’m a fan of keeping things simple, but it is possible that your unique bridge project would benefit from one of the more exotic designs.

Joseph Strauss, the engineer of the Golden Gate Bridge, was like many bridge engineers and builders in the late 19th and the first half of the 20th Century. He did not design a bridge with an "expected service life" as is done today. He designed a bridge that if properly maintained and cared for should last indefinitely.

'Innovative' FIU bridge was a modern take on an old design. And vulnerable to failure. - Miami Herald

'Innovative' FIU bridge was a modern take on an old design. And vulnerable to failure..

Posted: Wed, 21 Mar 2018 07:00:00 GMT [source]

In an ideal world, bridges should be prioritized for retrofitting that are critical for maintaining post-disaster traffic flows at pre-earthquake levels. This change would put a greater focus on post-earthquake evacuation, rescue, recovery and ongoing economic health. It will place less focus on retrofitting costs and possibility of damage.

Truss Design Options

Paul Hirzel’s River Structures are sited at the end of an existing single lane unpaved road cut into a hillside near Juliaetta. As a live-work space among a winery and vineyard, the project includes two context-specific structures called the Flood Plain House and the Fishing House. In this guide, you’ll learn how to design and verify a double timber beam for bending, shear, deflection and how to size the connectors between the 2 beams. – Top chord– Bottom chord– Diagonals (sometimes called strut or tie)– PostsHowever, this can vary depending on the truss type.

The most common and serious seismic problems happen at the bearings and bearing seats. However, it’s relatively easy and inexpensive to prevent the failure of bearing and expansion joints. This can be done by adding restraining devices and bearing seat extensions, along with strengthening bearings or replacing them. When priorities are being set, this is a relatively small-effort, low-cost undertaking that could provide significant long-term benefits. The key bridge components that must be considered when evaluating retrofitting strategies are the superstructure, substructure and foundation. The potential level of damage sustained by bridges during and after earthquakes should also be taken into account.

❗Be aware that the snow and wind load both get applied differently than the self-weight. Trusses are commonly used in roof and bridge structures, but there are a lot of different types. The Howe truss, patented in 1840 by William Howe, a millwright from Massachusetts, is very similar to its friend the Pratt truss; except that its diagonals face the opposite direction (away from the centre). The small change simply means a change in direction of where the force is applied. Originally, because their larger parts were constructed from wood, it was a popular design because it was cheaper to build.

However, it is important that the influence line analysis of the bridge be carried out, in order to determine the wheel load location that will produce the worst effects on the structure. All other environmental loads and indirect actions will not be considered. Truss enables the creation of light structures that can span large distances and endure very heavy loads. In its most basic form, a truss is a structure that is taking advantage of the inherent stability and the weight distribution of triangle. The web of such triangles can be joined, and resulting effect causes stress to be evenly distributed across the entire structure that can be dramatically more lightweight than the walls created from strong materials.

For instance, a little review of the design of the bottom chord shows that there is still room for reduction of the member size, while the same cannot be said for the web members. The truss bridge has been modelled on Staad Pro software as shown below. The top of the truss bridge (top chord) will be braced using UB 254x146x37 members in a K-truss arrangement (see below) to restrain the top chord from sway under wind action.

In fact, the latest infrastructure report card from the American Society of Civil Engineers rated approximately one out of every eleven U.S. bridges as structurally deficient. The final step in the inventory and evaluation process was to apply the evaluation system to the survey population. To ensure consistency, Caltrans developed guidelines for applying the criteria, which were as specific as possible, particularly with respect to the more subjective categories. When the guidelines were applied to all the bridges in the survey population, a computer database program generated lists of bridges ranked numerically. Made among a landscape of stone cliffs, pine trees and heather, this house is located on the island of Viggsö in the Stockholm archipelago. The private residence was spatially organized into three parts that are ordered by a simple wood structural system.

The bridge is one of the largest and most-well known examples of Art Deco architecture. The bridge features the main suspension spans, but its approach spans should not be overlooked. In addition to a series of deck truss spans supported by intricate steel bent supports, there is a beautiful trussed arch span over Fort Point. A beam is said to be cantilevered when it projects outward, supported only at one end. A cantilever bridge is generally made with three spans, of which the outer spans are both anchored down at the shore and cantilever out over the channel to be crossed. The central span rests on the cantilevered arms extending from the outer spans; it carries vertical loads like a simply supported beam or a truss—that is, by tension forces in the lower chords and compression in the upper chords.

In the case that the Queen post truss is used as a roof structure, the static system could look like in the picture below. In the case that the King post truss is used as a roof structure, the static system could look like in the picture below. The vertical central member connecting the bottom chord and the ridge is the king post, and the diagonals are called struts. The Pratt truss is characterized by its horizontal top and bottom chords, which are connected by an inclined diagonal. The Howe truss is characterized by its horizontal top and bottom chords, which are connected by an inclined diagonal.

The vertical members of the web are spaced at 2.5m each and the total length of the bridge is 25m. Space Frame – Truss designs can also be made in 3 dimensions, with tetrahedron being the most simple and commonly used of space truss. The mesh of space frame elements is most commonly used in the construction of “floors” built on top of just a few load bearing points that need to carry very large weight on top of them. Learning how to design a truss bridge takes time and a detailed understanding of engineering principles.

In order to prevent future damage and losses, bridges that are at risk must be identified, evaluated and retrofitted to make them less vulnerable to seismic activity. The recent earthquakes in California have more and more people thinking about the safety of bridges in areas that experience high levels of seismic activity. Using forms of ecology, Trunk House takes inspirations from the forest. As a small cabin in Victoria’s Central Highlands, the design includes living quarters, a kitchen and bedrooms that are surrounded by a timber structure.

No comments:

Post a Comment